Equipment use:

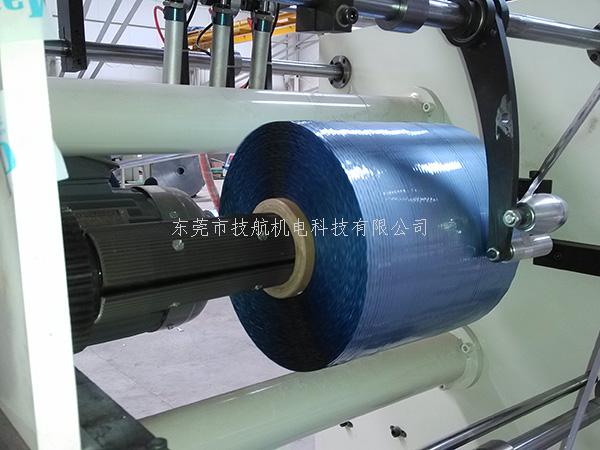

It is used for slitting and arranging reel materials such as composite film (such as aluminum-plastic composite), non-woven fabric, mica tape, PET, paper, etc.

Main performance features:

This equipment uses 1 set of 2KW servo motor and Delta servo drive, 14 sets of 2.2KW Dongyuan motor and 14 sets of Yaskawa inverter. The unwinding and redundant material rewinding adopts motor, 1 set of 3.7KW Tenet motor and One 3.7KW Yaskawa inverter is used for slitting speed control. Delta PLC and 10-inch Delta man-machine. 12 winding motors adopt speed control, synchronous with cutting motor speed, winding tension of each axis can be set digitally (12 SMC electric proportional valves), row width and overlap can be freely set, constant line can be set Speed operation, real-time display of winding diameter, from the inside to the outside, the overlapping distance remains the same, the maximum operating line speed is 200M/MIN, the machine has two working modes, common winding method and skip-type winding method, can be on the man-machine One-touch switching. The product has a smooth end surface and a beautiful surface.

The main technical parameters:

1, the machine speed: 0 ~ 300m/min

Winding speed: 0 ~ 200m/min (according to material material, thickness and product quality requirements)

Raw material width: 5MM-40MM

Unwinding diameter: 800mm

Winding diameter: 400MM (customized according to customer requirements)